-

Fermentation Bio-Reactor

The FBR (Fermentation Bio-Reactor) fermentation bioreactor purification tank is an integrated rural sewage treatment equipment designed to address the high requirements for nitrogen and phosphorus removal in rural sewage in China. It utilizes Futong's proprietary FB series functional bacteria (primarily including denitrifying bacteria, polyphosphate-accumulating bacteria, oil-removing bacteria, and various COD-reducing bacteria, the main bacterial species are derived from the environment itself) and incorporates Japanese purification tank equipment manufacturing concepts, featuring stable compliance, long service life, intelligent management, and economic applicability.

Send Email Details -

SMC Septic Tank

The basic principle of an SMC septic tank is to utilize the sedimentation effect caused by the fact that parasite eggs have a higher specific gravity than the fecal-urine mixture, as well as the principles of anaerobic fermentation, liquefaction, ammonification, and biological antagonism in a sealed environment to remove and kill parasite eggs and pathogens, control the breeding of mosquitoes and flies, and thus achieve the purpose of harmless treatment of feces. A three-compartment septic tank consists of three interconnected compartments connected by a connecting pipe.

Send Email Details -

Single-family Purification Tank

Futong purification tank employs a mature and stable A2/O process combined with an embedded biological dosing pack. The effluent from this micro-powered system meets the Class I standard of the "Discharge Standard of Pollutants for Municipal Wastewater Treatment Plants" GB18918-2002, and can be further improved by adding constructed wetlands for advanced treatment.

Send Email Details -

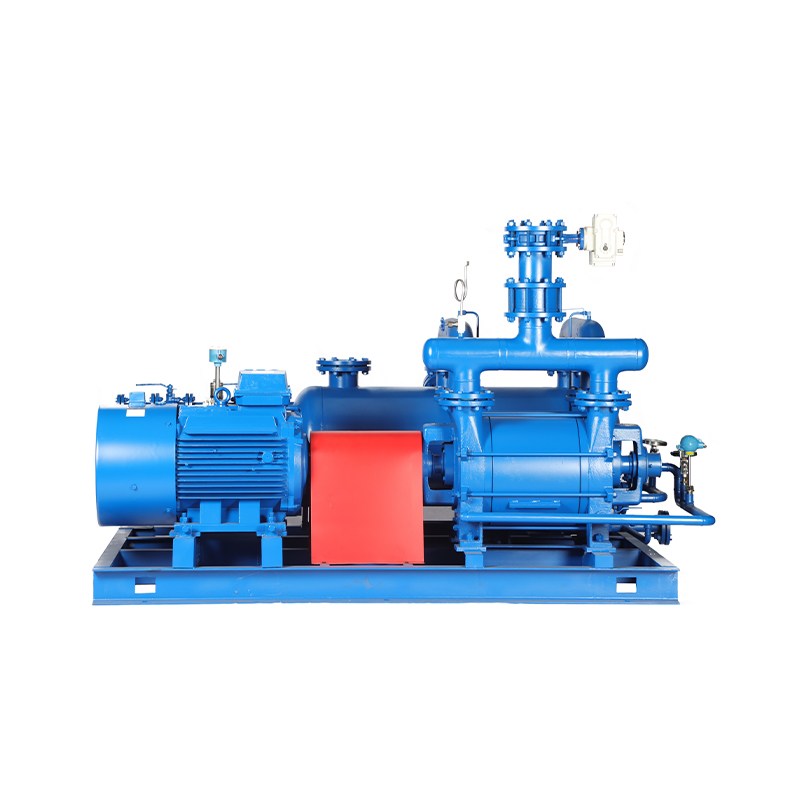

Liquid Ring Vacuum Pump (Unit)

2FV5

Send Email Details

2FV6

2FE1

2FE3

The liquid ring vacuum unit is a closed unit consisting of one or more (one active and one standby, two active and one standby, etc.) liquid ring pumps, gas-liquid separators, working fluid heat exchangers, a common base, a control cabinet, and other equipment, as well as pressure gauges, thermometers, liquid level gauges, and other instruments. The pumped medium enters the liquid ring pump and enters the gas-liquid separator together with the working fluid for gas-liquid separation. The gas is discharged, and the working fluid enters the heat exchanger, where it is cooled by cooling water and then returns to the liquid ring pump.